When tackling DIY projects, many Makers will search through their existing collection of useful but unused materials they have lying around the garage. This well-intentioned approach to upcycling is noble but probably not the best approach when making something as important as your wedding ring. Having the right materials and tools for the job make all the difference in the level of difficulty and finishing details. When handmaking a wedding ring metal matters

Type of Metals for Wedding Rings

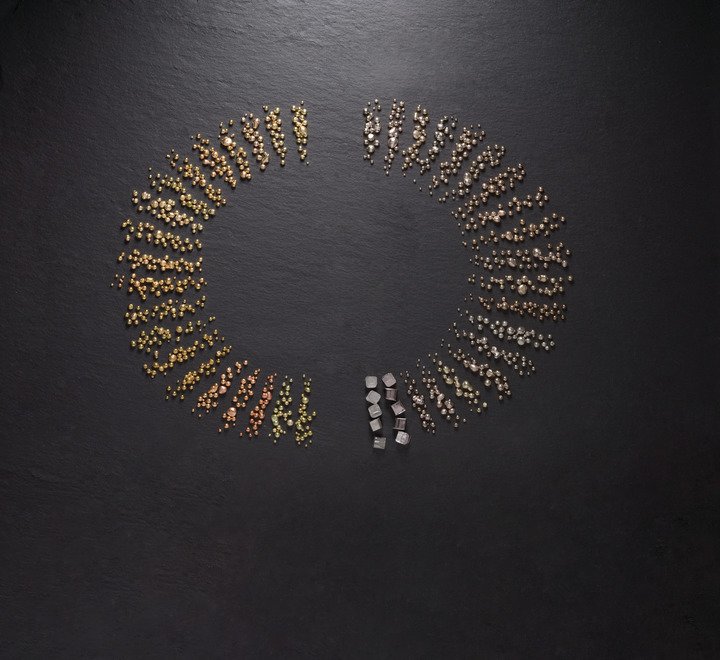

It is true that “gold is gold” 24K pure gold is unambiguous. Without diving into details of metallurgy, in modern times it is unlikely that anyone is producing jewelry out of pure 24K gold. A wide range of other metal alloys, such as silver, copper, palladium, etc. is used in combination with 24K gold to produce different colors and karats of gold.

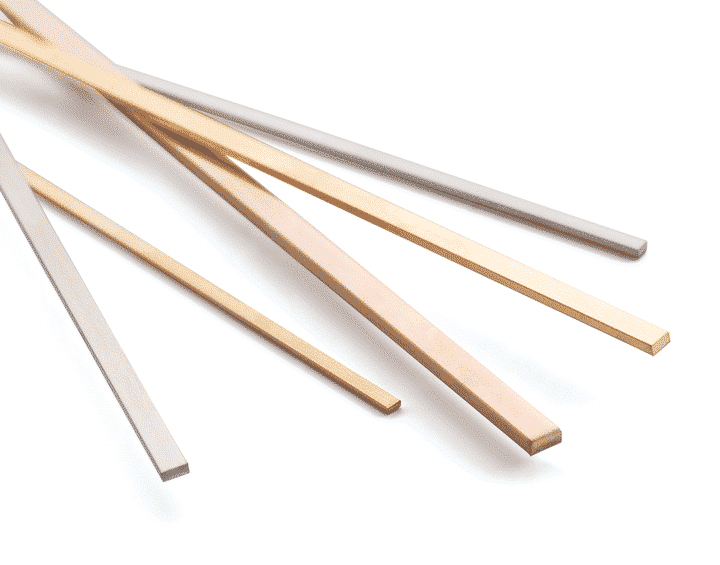

Yellow is the natural color of gold, however, when working with 18K or 14K gold you will notice a slight variation in color. This is due to the 18K gold being 75% pure gold while 14K is 58%. Other colors such as rose gold and white gold are achieved by introducing additional metals into the mix. Rose gold is achieved by a greater percentage of copper. White gold is achieved with silver and either nickel or palladium.

There are nuances to working with each color and karat of gold. The different types of white gold are probably the most sensitive. Nickel is a common irritant to people’s skin and because of this, nickel-based white gold often causes skin irritation. Nickel alloyed white gold is also brittle and not ideal for fabrication. Nickel white gold is often electroplated with rhodium to help give it a more brilliant white look. This “bleach white” plating is temporary and will wear off after a year or so of normal wear.

White Wedding Ring Metal

In contrast, palladium white gold is hypoallergenic, malleable with good ductility, and requires no plating. The properties of 18K and 14K palladium white gold are similar but do also have some slight variations in color and workability. It is ideal for fabrication projects and produces excellent finished results.

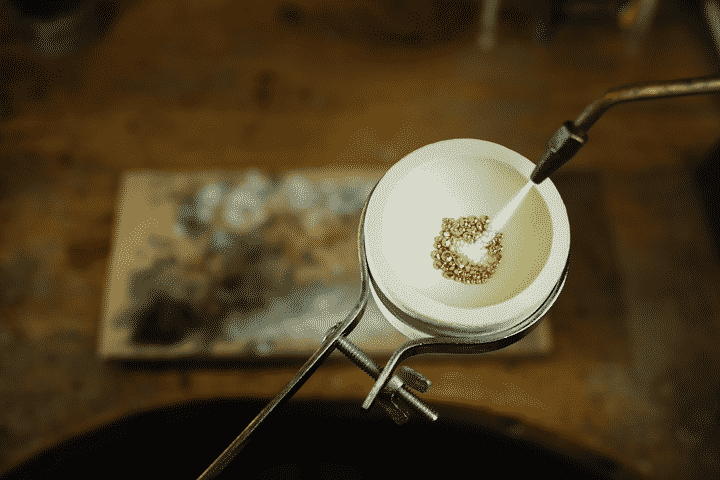

The different ways gold can be alloyed are some important to consider when making your own wedding rings. Recycling old, unwanted scrap jewelry with unknown variations in alloys can create challenges in the production process. Using old chains or scrap jewelry to create a highly finished piece of quality jewelry is challenging for anyone, especially a novice jeweler. The best approach for a beginner is to start with a “known” material.

Working with a known material will save time and make achieving a high level of finish hassle-free. Issues with cracking and pitting can be avoided when using the appropriate materials for the job.

Need Help Making a Wedding Ring?

Working with a professional jeweler, who is familiar with the ins and outs of all the materials available is probably the most efficient way to produce a high-quality piece of unique, custom wedding jewelry. Having a coach and mentor through the DIY process is always helpful and is exactly what Joseph at LaProng does for you. Sign up for a DIY Wedding Jewelry Workshop to make an engagement ring or wedding ring in a hands-on DIY workshop experience.

Get access to high-quality, ethically sourced materials, and professional coaching. In the LaProng DIY workshops you can choose from 18K or 14K Yellow, Rose, or White gold. Book your workshop and start the design process that includes picking out the best materials for what is likely your once-in-a-lifetime DIY project.