Have you ever heard the old saying, you don’t use a sledgehammer to crack a nut? This fun old saying is a great example of how having the right tool for the job matters. It is all the more ironic of an example for a jeweler since any good jewelry studio will have a wide variety of hammers that may be very well suited to crack open a nut! That said, when handmaking a wedding ring, you must have the right hammer!

Hand Tools

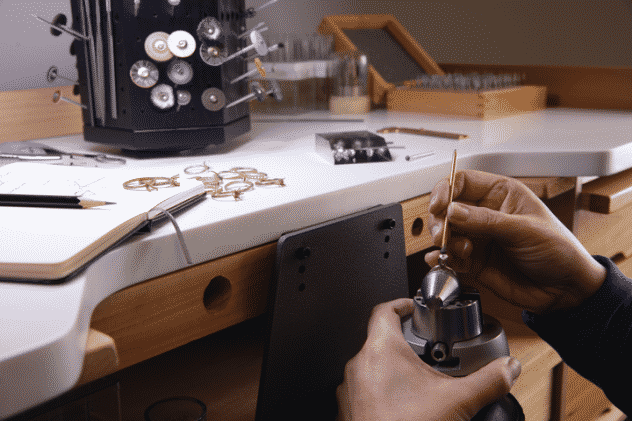

Not only will a typical jewelry studio have a great collection of hammers that have a very specific purpose, but there will also be many other less familiar specialty tools. The tools a jeweler would use to make a wedding ring will vary based on the production method, but basic hand tools such as small pliers, needle files, and small frame saw are the must-haves.

Strategy for Handmaking a Wedding Ring

When it comes to handmaking a wedding ring the two primary methods of production are fabrication or casting. The decision on which method you might use is influenced by the complexity of your design, cost, and what tools and equipment you already have available. One is not necessarily better than the other and both methods can produce beautiful custom-made jewelry.

Casting

The casting process is known as lost wax casting. This method uses a master model, which nowadays is often printed on a 3-d printer. The master model is covered in plaster and placed into a kiln. The kiln will burn out the master model leaving a negative cavity. That cavity is then filled with melted metal. This method usually requires more equipment at a greater cost than the fabrication method.

Fabrication

The fabrication process typically starts with preformed pieces of sheet metal, wire, or a piece of metal known as an ingot. Then the material gets hand-manipulated. It is formed, stretched, soldered, engraved, and worked into a piece of fine wedding jewelry. This method usually requires less of a need for special equipment. Fabrication of wedding jewelry can limit complex design possibilities but it is still the most viable option for someone with no jewelry-making experience wanting to make a DIY engagement or wedding ring.

Work With What You Have

You may already have many of the hand tools necessary for a fabrication method. If not, there are many toolsets available to get you started. As when buying any tools, you usually get what you pay for. However, if you are only looking for tools to complete a single project you can get by with something from Amazon. You might get by using the existing mallet, a small saw, and a Dremel you already have in your garage. When it comes to soldering precious metals properly, you may have to seek out some specific tools to achieve the seamless invisible solder joints you want in a piece as special as an engagement or wedding ring.

Project Assistance to Handmake a Wedding Ring

If you are interested in tackling a DIY wedding ring but still have questions or are interested in a project coach, check out the workshops offered by LaProng Jewelers. Step-by-step coaching will help you make your wedding ring, hands-on in a one-day, DIY workshop excursion. It is an award-winning experience that will help you make the most important piece of jewelry you will likely ever wear!