Ring Making 101

Make it

The process to make a classic-style wedding ring can be done in a few different ways. Techniques of casting, fabrication, machining or a combination of both can be used to make a ring. However, in the DIY workshop, the approach is to keep it simple with basic fabrication techniques. This approach is intended to be straightforward to accomplish a professional, high-quality result in the designated amount of time in your workshop.

In the DIY wedding jewelry workshops we go through the process to measure, cut, shape, solder, and finish your rings out of your chosen metal. You will need to work with a few different hand tools that include; a jeweler’s saw, torch, files, and other specialized equipment to create your own unique wedding rings. Most people will fabricate and finish their rings in approximately 6 hours. In the end, you take home your creations at the end of the workshop!

Measure it

As with every project, planning is key! First, you will figure your ring size and determine how much metal you will need to make your ring. A couple of quick measurements and a few simple calculations will give you the plan to get started. You measure and do a little math before moving on to the next step.

Cut it

You will need to use a jeweler’s saw to cut your ends clean. once complete, you will have formed what we call your ring blank. Much like a wood saw, the blade should do most of the work, but a consistent and straight cut isn’t necessarily easy work.

Shape it

Once your ring blank is at the correct length, you will begin to shape and form it into a ring. You will use forming tools and a little muscle to bring each end of the ring blank together.

Soldier it

Once your ends have come together perfectly, you will be guided through the process of soldiering. You will begin to heat your ring with the torch and apply solder to close the ring and bind it together. This process is always fun with a little fire to heat things up!

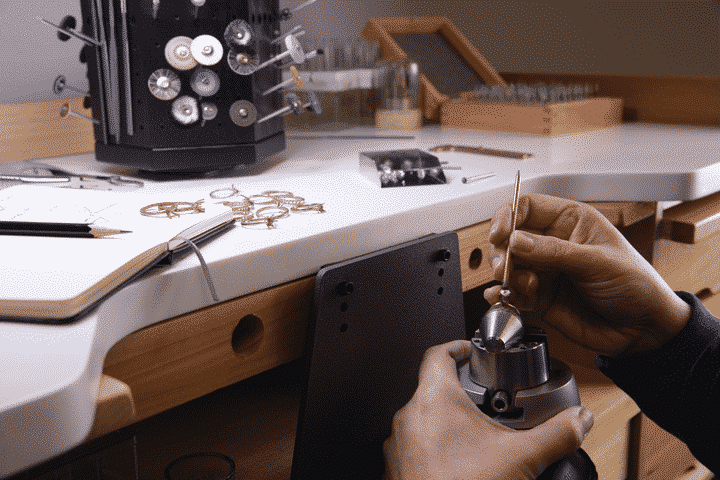

Round and Polish it

After soldering you will begin cleaning your ring up and start preparing your wedding rings for the final polishing step. You will use an assortment of files and or sandpaper to remove excess solder and tool marks.

The last step in the process will be to ensure your ring is round and the right size. After that, you will add the final finish or polish to your new custom-made wedding band!

Still, want to know more? Contact Us or send us a message and we will contact you. If you are ready to get to work Book your workshop now online.

Wear it!